3D Scanning Solves Pattern Problem

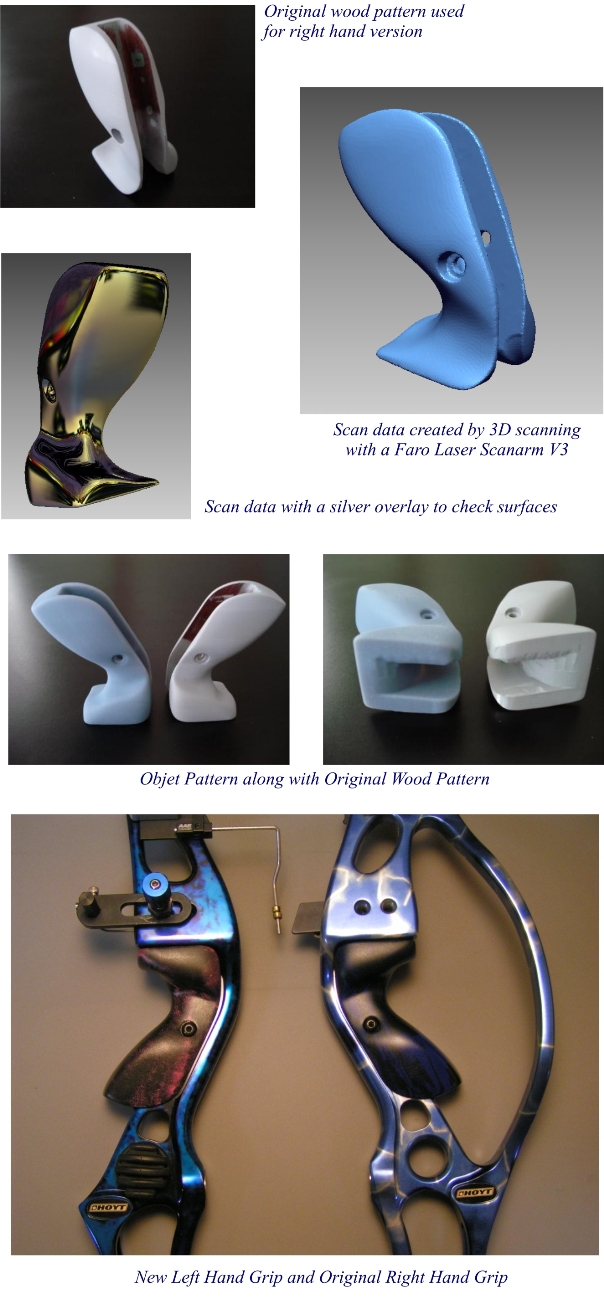

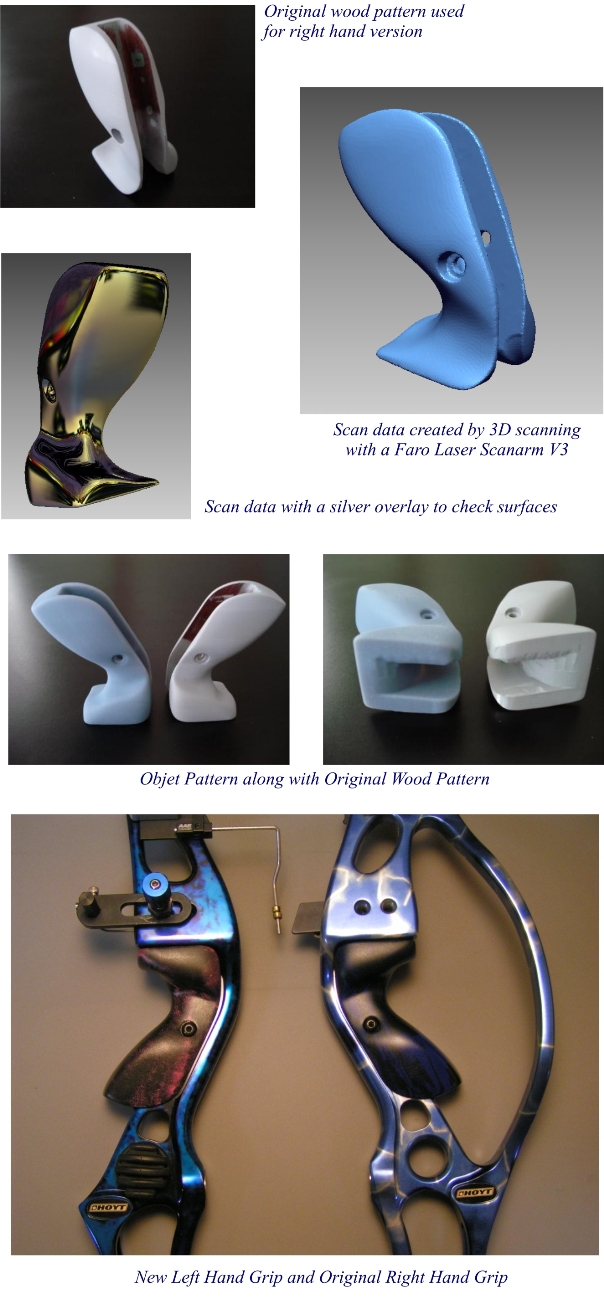

Jager Archery of Greeley, Colorado, produces custom grips for recurve and compound bows. Each grip is hand made by mixing material and pouring it into a silicone RTV mold. Hand carved wood patterns are used as patterns to create the RTV molds.

Jager's customers started asking for a left hand version of the grip so they proceeded to hand carve the left hand pattern. They found it impossible to recreate the exact geometry of the right hand version. It was time consuming, inaccurate and not always practical since left-handed bows required for fit-up are expensive and rare.

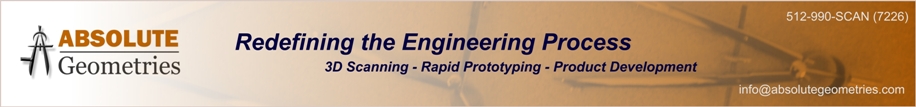

Jager turned to Absolute Geometries for assistance in reverse engineering the grip. A Faro Laser Scanarm was used to scan the hand made grip, producing a digital copy of the geometry. This scan data was then cleaned up to produce a watertight STL file that could be used in Rapid Prototyping. The STL file was mirrored and shrink was added for the tooling process.

Absolute Geometries used an Objet Eden 500 to produce the Rapid Prototype pattern to be used in the RTV tooling process. Because of the small layer thickness used in the Objet process, very little cleanup of the pattern was required. Jager Archery proceeded with building new tooling with their proprietary tooling process. The Objet pattern worked just as well as the wood patterns used in previous tooling. The new left-hand grips were produced in less than two weeks from the time the pattern was sent to Absolute Geometries. Making the pattern by hand would have added several days to the process and would have produced a less-than-perfect version of the grip.